Overview

The Department of Mechanical Engineering was started in the year 2009 with an intake of 60 students. The department has well equipped state-of the art laboratories with advanced software. The programs are designed to equip students with the knowledge and skills necessary to excel in today’s rapidly evolving technological landscape.

The department has 4 highly dedicated and qualified faculties with a good blend of experience from both Academics and Industry. Out of which 2 Associate Professor with Doctoral Degrees in Mechanical Engineering and 2 Assistant Professor have more than 15 years of experience. The 2 faculty members pursing Ph.D with a minimum qualification of M.Tech/ME , with a good academic and research experience. Within a span of 15 years, the department has reached Centre of Excellence by Robert Bosch and having an MoU with several industries, attaining good academic results, conducting several Internal Webinars, National webinars, seminars, conference, workshops, industrial visit, FDP’s, Industry –Institute interactions at State and National levels. Currently, the department offers Doctoral degree by Research Program in addition to UG Program affiliated to Visvesvaraya Technological University (VTU), Belagavi, Karnataka.

A total grant of Rs. 28.54 lakhs was received from the Central and State agencies like AICTE, KSCST, VTU, EDII, VGST, IEI etc. Teaching faculty members have published 55+ Research Publication in reputed international journals. Also obtained 01 Indian patent and 02 patents are awaiting for the grant under the ACS College of Engineering

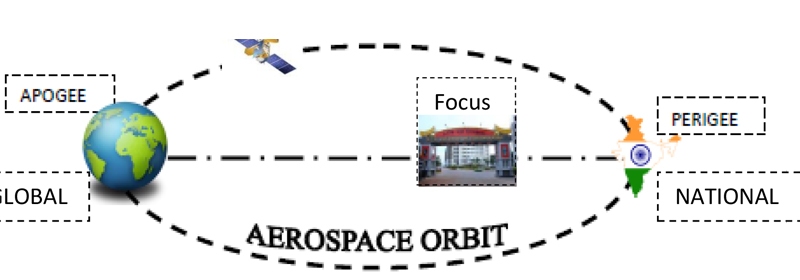

Vision

To create a center of global standard for imparting education in Mechanical Engineering field and conducting research at the cutting edge of technology to meet the current and future challenges of technological development.

Mission

To build enabling environment for excellent teaching, learning and research in order to produce entrepreneurs and innovators in the field of Mechanical Engineering for sustainable improvement.

Duration

4 Years

Eligibility

Marks – General : 45% Aggregate

Marks- SC/ST/OBC : 40% Aggregate

Eligibility Subject : Physics, Chemistry, Mathematics

Eligibility – Exam : 10+2(Physics, Chemistry, Mathematics) with CET/COMED-K/JEE any one Rank is compulsory

Lateral Entry (Admission to 2nd Year) : 10+3 (Diploma in Mechanical Stream)

Accreditation, Approvals, and Recognition

- Approved by AICTE

- Affiliated to VTU

- Approved Research Center

Career Opportunities

The girth of the Mechanical Engineering degree offers a wide range of career opportunities. The key characteristics of the profession are its breadth, flexibility, and individuality. The career paths of mechanical engineers are largely determined by individual choices, a unique advantage in a dynamic world. Mechanical engineers are capable of working in a wide variety of industry sectors, and new modern technologies will create industries that don’t exist today. Mechanical engineers are no longer confined to the traditional industries of aerospace, automotive, and manufacturing, but are also employed extensively in important emerging areas, such as nuclear technology, robotics, biomedical technology and energy systems. Furthermore, our students acquire valuable skills in creative thinking, critical analysis and teamwork, which are highly sought after in any engineering industry, consulting and management.

Program Outcomes (POs) as derived from Graduate Attributes

Demonstrate knowledge of mathematics such as multi-variable calculus, Differential equations, science and engineering.

Demonstrate an ability to identify, formulate and solve mechanical engineering problems.

Model, analyze, design and realize physical systems, components or processes.

Plan and conduct an experimental program and evaluate the results.

Use modern engineering tools, software and equipment to analyze problems.

Understand the global, societal context of engineering.

Provide mechanical engineering solutions to green and sustainable development.

Demonstrate knowledge of professional and ethical responsibilities.

Work with others to accomplish common goals.

Communicate effectively in both verbal and written form

Develop confidence for self-education and ability for life-long learning.

Complete a project with financial management skill.

Short Term Goals

- To create an infrastructure for a professional knowledge learning centre.

- To promote learning activity to develop the recent technology and getting patents etc.

- To strengthen the relationship with industrial and academic partners.

Long Term Goals

- To design an effective curriculum for interactive learning.

- To upgrade laboratory with latest instruments for advanced research.

- To incentivize research, plan fiscal policies for strategic initiatives.

Programme Educational Objectives

PEO-1:

Mechanical Graduates will have strong fundamental technical knowledge and are capable to develop core competency in diversified areas such as Production, Design, Thermal, Industrial and allied fields with the use of software tools to expand their knowledge horizon and inculcate lifelong learning.

PEO-2:

Graduates will have effective communication, leadership, team building, problem solving, decision making skills, and software and creative skills by understanding contemporary issues there by contributing to their overall personality and career development.

PEO-3:

Graduates will practice ethical responsibilities and service towards their peers, employers, society and follow these percepts in their daily life.

Profile of Mechanical Engineering Department

Mechanical Engineering is one of the oldest and broadest Engineering disciplines, which apply the principles of physics and materials science for analysis, design, manufacturing and maintenance of mechanical systems. This field is growing day by day due to increasing requirement in Industries leading to advances in Technology. In this direction, a proper training for the students is needed to become successful. Keeping this in mind, The Department of Mechanical Engineering started in the year 2009 with the aim of providing quality education to the students. The department offers an undergraduate programme leading to B.E. (Bachelor of Engineering) and a post graduate program Master of Technology in Product Design & Manufacturing (2013-2014) affiliated to Visvesvaraya Technological University, Belgaum. The department is recognized as research center by VTU, Belgaum.

The department encourages the students to build a firm foundation through core courses, taught by the experienced faculties and then progress towards more specialized topics like Robotics, MEMS etc. The department has laid down an action plan for special training to the students in the thrust areas like CAD/CAM, Finite Element Methods (FEM), Computational Fluid Dynamics (CFD) etc.

The faculty members are proficient in diverse areas like Production, CAD/CAM, Thermal Engineering, Computational Fluid Mechanics, Robotics and Machine Design. Our department always supports institution-industry collaboration in the form of training, consultancy services and contract research.

CAED Lab/CAMD Lab

In the Computer Aided Engineering Drawing (CAED) Lab, the students learn and practice Engineering drawing using the software called Solid Edge. There are 65 personal computers with LAN connection and LCD projector facility. All the systems are having uninterrupted power supply by UPS batteries. There is also printer facility provided to the students for the purpose of documentation of their work.

This facility is utilized by first year students for engineering drawing and by second year students for machine drawing class.

Material Testing Lab

This lab is part of the curriculum of second year Mechanical Engineering. The lab has various material testing equipment’s like Universal testing machine, Torsion testing machine, Hardness testing machines, Impact testing machine, Furnace, Wear testing machine, Non-destructive testing.

Foundry and Forging Lab

This lab is part of the curriculum of second year Mechanical Engineering. It has two sections, Foundry & Forging. In Foundry basic work skill of making moulds with the mould sand is taught to the students. In addition to it, sand testing experiments are also taught. The major equipment’s available are sand sieving unit, compressive strength testing, permeability test, etc.

In the forging section, the basic work of shaping the metals by forging operations is taught.

Mechanical Measurements and Metrology Lab

Mechanical measurements and Metrology Lab has various measurement and calibration equipments. The major measuring instruments available are Profile projector, Tool maker’s microscope, Floating carriage micrometer, Autocollimator, etc. The major calibration equipments are Sine bars with slip gauges, Thermocouple, Sine center, Strain gauge, Pressure gauge, etc.

Machine Shop

In machine shop the skill of machining operations using various machine tools are taught to the students in their second year of Mechanical engineering. The major machine tools available in the Machine shop are Lathes, Shaping machines, Milling machines, Grinding machines, and Drilling machines. The various jobs taught in the lathe machine are turning, taper turning, parting, thread cutting etc. Also the gear cutting operation and shaping operations are taught.

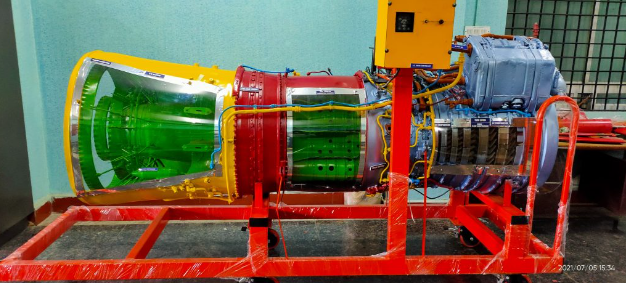

Energy Conversion Shop

This is part of fifth semester Mechanical Engineering curriculum. The major equipments available are Four stroke single Cylinder Diesel Engine, Four stroke single cylinder petrol engine, Two stroke single cylinder petrol engine, Four stroke Multi cylinder petrol engine, Abel Flash & Fire point testing, Pensky Martin Flash & Fire point testing, Viscometer, Calorimeter, Valve & Port timing, and Planimeter.

Fluid Mechanics and Machinery Lab

This is part of fifth semester Mechanical Engineering curriculum. The major equipments available are Pelton Wheel Turbine, Francis Turbine, Kaplan Turbine, Flow Measuring Equipments, Orifice meter, Air Compressor, Impact of jet on Vanes, Notches, and Centrifugal Pump.

CAMA/CIM Lab

This lab is setup for Computer Aided Modelling and Analysis lab for 6thsemester Mechanical engineering and Computer Integrated Manufacturing lab for 7thsemester Mechanical engineering. The lab has 22 workstations installed by SWAN SOFT CNC Simulator

Heat Transfer Lab

This is part of sixth semester Mechanical Engineering curriculum. The major equipments available are Air Conditioner, Refrigerator, Heat Exchangers, Heat Transfer Coefficient of a Composite Wall, Heat Transfer Coefficient in free Convection , Heat Transfer Coefficient in a forced convection, Flow through a Pipe, Emissivity of a Surface, Stefan Boltzman Constant, LMTD & Effectiveness in a Parallel Flow and Counter flow Heat Exchanger, Boiling of Liquid and Condensation of Vapour, Transient Conduction Heat Transfer, Effectiveness on Metallic Fin, and Thermal Conductivity Equipments.

Design Lab

This is part of seventh semester Mechanical Engineering curriculum. The major equipments available are Journal Bearing, Polaris cope, Governors, Vibration Test Rig, Balancing Apparatus, Deflection of Curved beams with strain gauge and strain indicator, Gyroscope, Whirling of Shafts, and Diffused light Polari scope.

Well-equipped classrooms and seminar hall with modern audio-video equipment’s have been deployed for better student-teacher interaction, productivity and communication. It makes teaching and learning is better.

The department having the following laboratories with the state of art equipment’s, instruments and computational facilities: Workshop Practice, Computer Aided Engineering Drawing, Metallography and Material Testing, Foundry and Forging, Metrology & Mechanical Measurement, Machines Shop, Fluid Machinery & Fluid Mechanics, Energy Conversion Engineering, Heat and Mass Transfer, Computer Aided Modeling & Analysis, Computer Integrated Manufacturing and Automation, Design etc.

The department also provides the required facilities for the research scholars and the faculty to carry out their research work. Research areas of the department are Composite Materials, Nanomaterials, Bio-diesel Fueled CI engines, Product Design and Development, Bio-Gas, CFD and Rural Energy Systems etc.